Abstract

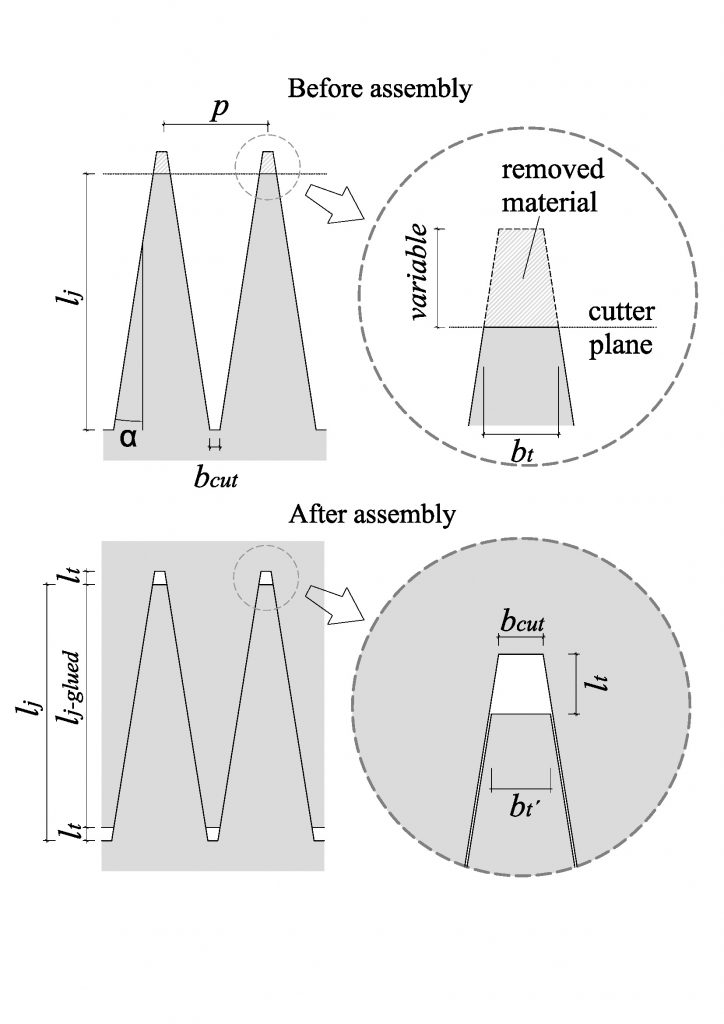

The present research focus on the performance of finger-joints for the development of novel engineered laminated products made of Eucalyptus globulus using 1C-PUR adhesive type I suitable for outdoor use, taking the advantages of the high mechanical properties and great natural durability that this species offers. The influence of the elastic modulus of the eucalyptus, geometric parameters of the joint and end pressure on the finger-joint bending strength is investigated. Also the influence of end pressure on the tip gaps is analyzed. Small tip width and high finger length produce the best results when the gap is reduced to a minimum but avoiding contact at the finger-tip. High characteristic strengths levels are obtained with suitable joint configuration indicating a possible strength class of GL48c or even higher.