Title (acronym): Holistic implementation of European thermal treated hardwood in the sector of construction industry and noise protection by sustainable, knowledge- based and value added products (HOLIWOOD)

Reference: NMP2-CT-2005-IP011799-2

Funding: 6th EU-Framework Programme for RTD, Priority: NMP; Instrument: IP_SME.

Duration: 4 years (01/07/2005 – 30/06/2009).

Budget: 11.915.368,00 €

Financed amount: 5.997.467,00 € (UPM: 608.306,82 €).

Coordinator: PROFACTOR GMBH (Austria)

Consortium: 21 partners from 9 European countries

- PROFACTOR GMBH (Austria)

- MITTERAMSKOGLER GMBH (Austria)

- POPPE PREHAL ARCHITEKTEN ZT GMBH (Austria)

- EMPA – SWISS FEDERAL LABORATORIES FOR MATERIALS TESTING AND RESEARCH (Switzerland)

- UNIVERSIDAD POLITECNICA DE MADRID (Spain)

- HOLZWERK LEHMANN AG (Switzerland)

- LEDRO POWDER COATINGS BVBA (Belgium)

- LEDRO KEUKENS NV (Belgium)

- AUTOBAHNEN- UND SCHNELLSTRASSEN- FINANZIERUNGS-AKTIENGESELLSCHAFT (Austria)

- THE UNIVERSITY OF LIVERPOOL (United Kingdom)

- OBERMAYR HOLZKONSTRUKTIONEN GESMBH (Austria)

- MODULCAD S.R.O. (Slovakia)

- THERMOHOLZ AUSTRIA GMBH (Austria)

- MIRAKO-HOLZ GMBH (Austria)

- IBS – INSTITUT FUER BRANDSCHUTZTECHNIK UND SICHERHEITSFORSCHUNG GESELLSCHAFT M.B.H. (Austria)

- EINE WELT HANDEL AG (Austria)

- EBOEK, INGENIEURBUERO FUER ENERGIEBERATUNG, HAUSTECHNIK UND OEKOLOGISCHE KONZEPTE GBR, HILDEBRANDT, DR. KAHLERT, KÖNIG, WERNER (Germany)

- FERTÕ-TAVI NÁDGAZDASÁGI RÉSZVÉNYTÁRSASÁG (Hungary)

- GÒTIC GESTIÓ DE LA CONSTRUCCIÓ SL (Spain)

- TIGERWERK LACK- UND FARBENFABRIK GMBH & CO. KG. (Austria)

- VÄLINGE INNOVATION AB (Sweden)

Abstract

The goal of HOLIWOOD is the development and holistic industrial implementation of products made of thermal treated hardwood. Three product lines are followed:

- Load bearing structures for the construction of industrial eco²building (300-5000m2)

- Glue less solid wood flooring

- Noise protection barrier system

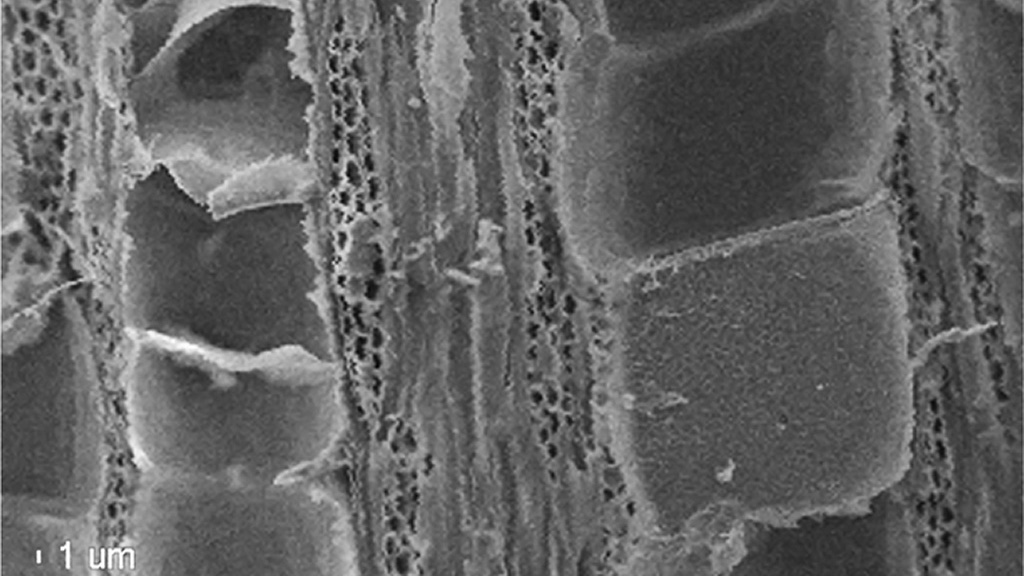

With these products the technical and economic breakthrough will be targeted for thermally treated wood exhibiting superior properties in terms of durability and sustainability. By this way, energy and resource consuming materials such as concrete, aluminium and plastics will be replaced. The research and development activities focus on gathering basic know-how concerning the wood properties, paying special attention to statics, acoustics and manufacturing.

The usage of Thermowood for load bearing construction parts is a technological innovation leading to a broad range of application in the house construction area. The integration into the construction of eco2buildings (showing less than 15 kWh/m2a maximum heating load) is a very promising approach for which the need has been expressed by leading architects in the sector.

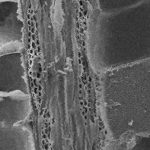

Thermal treatment of European hardwood species like beech allows their use also for long lasting exterior applications. Especially low-quality beech (i.e. red heard beech) commonly used for short lived and “low-value” products like firewood, raw materials for pulp and packaging, can be converted into a high quality raw material for long lasing products.

Thermally treated hardwood offers excellent durability equal to tropical woods. Beside this important property, the market claims additional functionalities. The interdisciplinary approach of HOLIWOOD therefore additionally aims at the development of functional coatings, based on powder coatings and sol-gel technology specially adapted to thermal treated hardwood. These nanocoatings shall basis on modular design, offer ecological coloration and inhibition of the wood greying for more than 20 years. For indoor use the focus is on additional functionalities, namely hydrophobic, oleophobic and scratch resistance properties.

The strong participation of SMEs demonstrates the importance of the investigated field of research in this traditional industrial sector. The consortium covers all necessary fields of R&D. Training and demonstration will prepare future costumers for the new products in due time. Exploitation strategies and demonstration activities complete the holistic approach in HOLIWOOD. For this purpose, an industrial eco²building with prefabricated walls made of thermally treated hardwood will be erected. For the noise protection barrier system, a demonstration track of approximately 1km made of Thermowood will be implemented.

Related publications

-

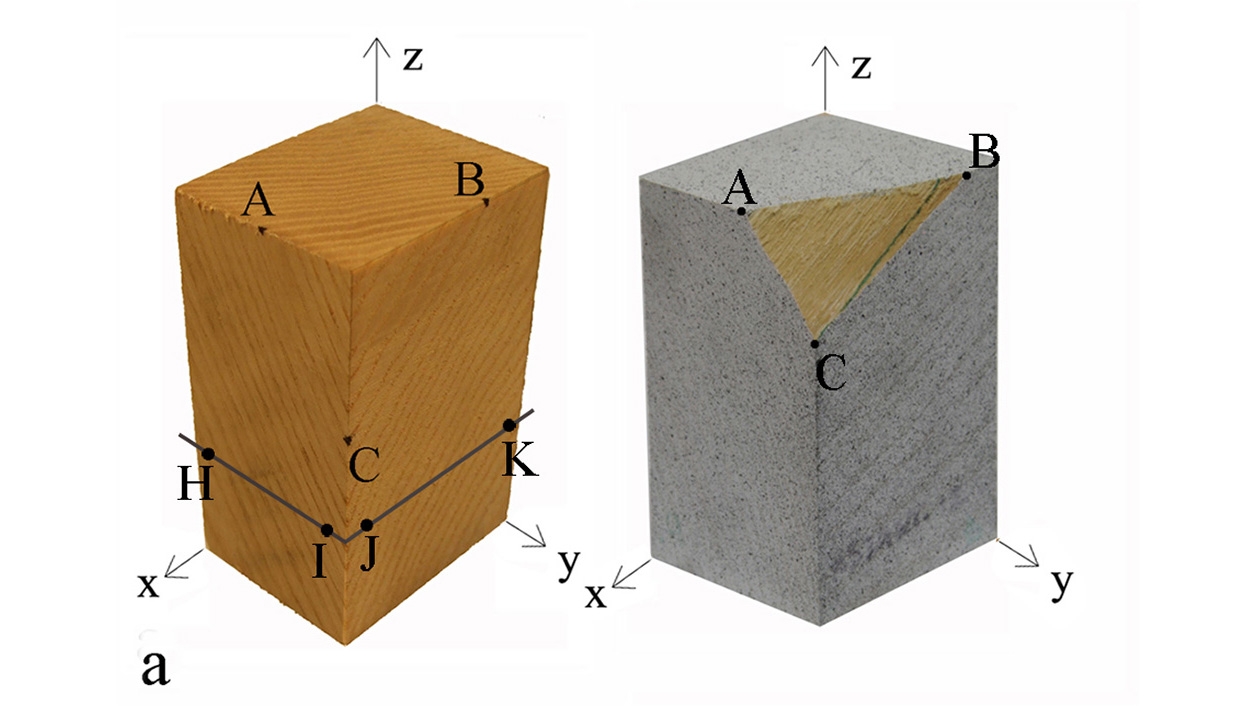

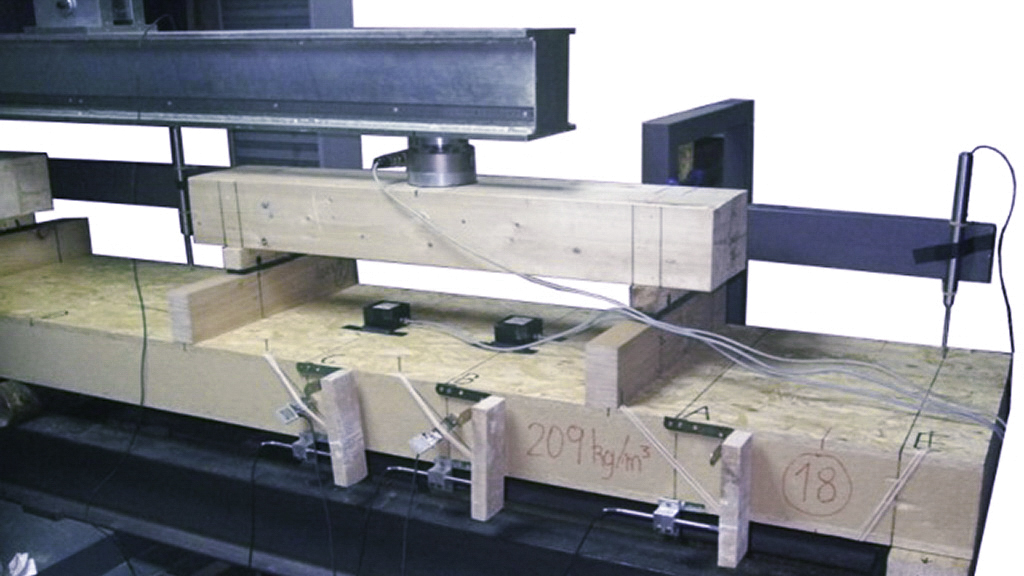

Gómez-Royuela JL, Majano-Majano A, Lara-Bocanegra AJ, Reynolds T. (2021) Determination of the elastic constants of thermally modified beech by ultrasound and static tests coupled with 3D digital image correlation. Construction and Building Materials, 302:124270.

-

Majano-Majano A, Fernandez-Cabo JL, Hoheisel S, Klein M. (2012) A test method for characterizing clear wood using a single specimen. Experimental Mechanics, 52:1079-1096.

-

Majano-Majano A, Hughes M, Fernandez-Cabo JL. (2012) The fracture toughness and properties of thermally modified beech and ash at different moisture contents. Wood Science and Technology, 46:5-21.

-

Majano-Majano A, Fernandez-Cabo JL, Xavier J. (2012) Characterization of clear wood by a single specimen: evaluation of first results and further improvements. 6th European Congress on Computational Methods in Applied Sciences and Engineering (ECCOMAS 2012), Vienna, Austria.

-

Fernandez-Cabo JL, Majano-Majano A, San Salvador Ageo L, Ávila Nieto M. (2011) Development of a novel façade sandwich panel with low-density wood fibres core and timber-engineering board faces. European Journal of Wood and Wood Products, 69:459-470.

-

Majano-Majano A, Fernandez-Cabo JL, Hoheisel S, Klein M. (2011) Characterization of clear wood by a single test. Madeira: Arquitetura e Engenharia, 12(28):45-57.

-

Majano-Majano A, Fernandez-Cabo JL, Hoheisel S, Klein M. (2011) Characterization of clear wood by a single test. 1º Ibero-Latin American Congress of Timber in Construction (CIMAD 11), Coimbra, Portugal.

-

Majano-Majano A, Hughes M, Fernandez-Cabo JL. (2010) A fracture mechanics study of thermally modified beech for structural applications. World Conference on Timber Engineering (WCTE 2010), Riva del Garda, Trento, Italy.

-

Fernandez-Cabo JL, Majano-Majano A, San Salvador Ageo L, Ávila Nieto M. (2010) A novel façade sandwich panel with low-density wood fibres core. World Conference on Timber Engineering (WCTE 2010), Riva del Garda, Trento, Italy.

-

Majano-Majano A, Hughes M, Fernandez-Cabo JL. (2009) Fracture characteristics and properties of thermally modified timber made out of beech. The 4th European Conference on Wood Modification (ECWM 2009), Stockholm, Sweden.